Condensation hoods

Condensation hoods

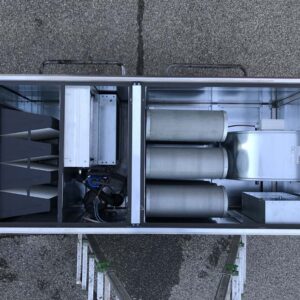

The Condensing units are built for the purification and deodorization of fumes coming out of kitchen hoods, which do not have the possibility of creating an external flue.

The machine is made with a load-bearing base in 30x30mm painted black tubular steel (except for the Cond 15 which is made only with an aluminum structure, given the limited weight), on which the anodized aluminum machine structure is fixed, with paneling double: internal panel in galvanized sheet metal, external panel in pre-painted sheet metal, internal lining with thermo-acoustic insulation.

Pre-filtration is carried out with pleated Viledon filters, in class G4, in accordance with the EN 779-2012 Em >90% standard, and rigid pocket filters, in class F9 in accordance with the EN 779-2012 Em >96 standard %.

The condensing system is made up of a refrigeration circuit composed of the following parts: rotary type refrigeration compressor, for small powers, and scroll type for higher powers, continuous pack heat exchangers, made of copper tubes and aluminum, and aluminum shoulders.

The refrigeration pipes are made with copper pipes brazed with an alloy of copper and silver or copper and phosphorus.

Safety, to protect the refrigeration circuit, is given by the high pressure switch with manual reset, by the low pressure switch (except for the Cond15 version), by the timer to delay the compressor starting, and by the circuit breaker (to protect of the compressor).

To collect the condensate (vapours, oils, fats), a stainless steel tray, Aisi 304, is installed below the heat exchangers, to be taken to the sewer via a siphon. To reduce remaining odors, activated carbon cartridge filters with high absorbent power are installed. Finally, a centrifugal fan is installed, directly coupled with an electric motor, to guarantee the right amount of intake air for the system.

Optional in the more complete machines, the pre-filtration is carried out with a double electrostatic filter and after the condensation group, before the active carbon filters, the ionizer and the ozonizer are inserted which help to reduce odors even more strongly.

The refrigerant gas expansion system varies depending on the power of the machine:

| Model | Type of Expansion |

|---|---|

| Cond15 | Capillary |

| Condition25 | Thermostatic valve |

| Cond50 | Electronic Valve |

| Cond60 | Electronic Valve |

FREE QUOTE

Or write to us for any information